Cardboard cores for paper mills: guide to choice

Cardboard cores for paper mills: guide to choice

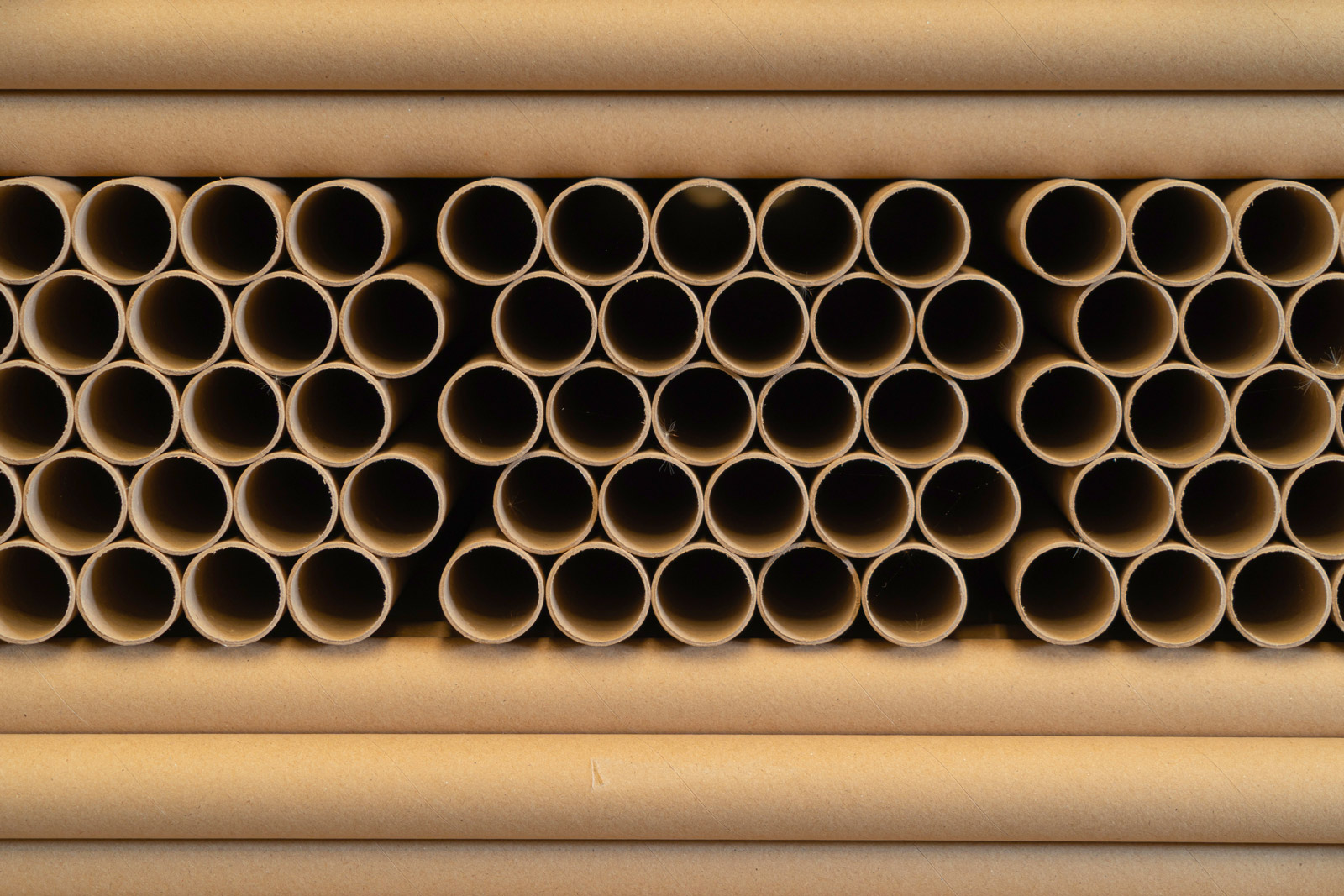

Paperboard cores for paper mills play a very important role in the production process of companies.

For this reason, when approaching the purchase of paperboard cores for paper mills, it is essential to be able to rely on a company that can meet your needs for technical features, customization, and sustainability.

Criteria for choosing paperboard cores for paper mills

Manufacturing companies such as industrial paper mills know the importance of making quality, durable and sustainable products for their customers.

Tubitex is aware of these goals and is constantly working to improve its product offerings, innovate its processes and materials, and maintain high standards of environmental compliance.

Variety of choice and customization

Each manufacturing company has unique needs, and it is essential that suppliers are able to meet them to the best of their ability.

The company chosen should ensure, for example, that different diameter and length sizes, corresponding to as many different applications for winding:

- Coated paper;

- Newsprint;

- Printing paper;

- Paper to be waved;

- Wrapping paper;

- Silicone papers

Paperboard cores for paper mills made by Tubitex, moreover, can be created ad hoc, or customized to suit the customer’s specific needs.

Specifications

In choosing paperboard cores for paper mills of high quality, it is necessary to check that the products meet specific criteria and have the following characteristics:

- High compressive strength;

- Remarkable straightness;

- Constancy of diameters;

- Dynamic robustness;

- Realization based on selected raw materials.

Sustainability

Environmental friendliness and eco-friendly production play an increasingly important role, as evidenced by EU Directive 2018/852 issued by the European Parliament, which supports waste and packaging reduction and recycling practices. Tubitex uses recycled cardboard for its cores, a material that combines flexibility and lightness with strength and reliability. It can be easily recycled, generating a virtuous circle that meets the needs of manufacturing companies without generating a negative impact on the environment.

Choosing efficient and environmentally friendly solutions has many advantages, one of which is creating a better corporate image.

Conclusion

Cardboard cores for paper mills: guide to choice. Sustainability, technological know-how and chosen raw materials are factors that hold great importance when choosing paperboard tubes for paper mills. The right board for an industrial business must meet certain quality standards and ensure reliability and durability.

Tubitex, an excellence of Made in Italy, is ready to meet the demands and meet the needs of paper mills with the professionalism and efficiency that sets it apart by making lightweight but sturdy products for all kinds of packaging.

For more information you can contact us through the contact form.