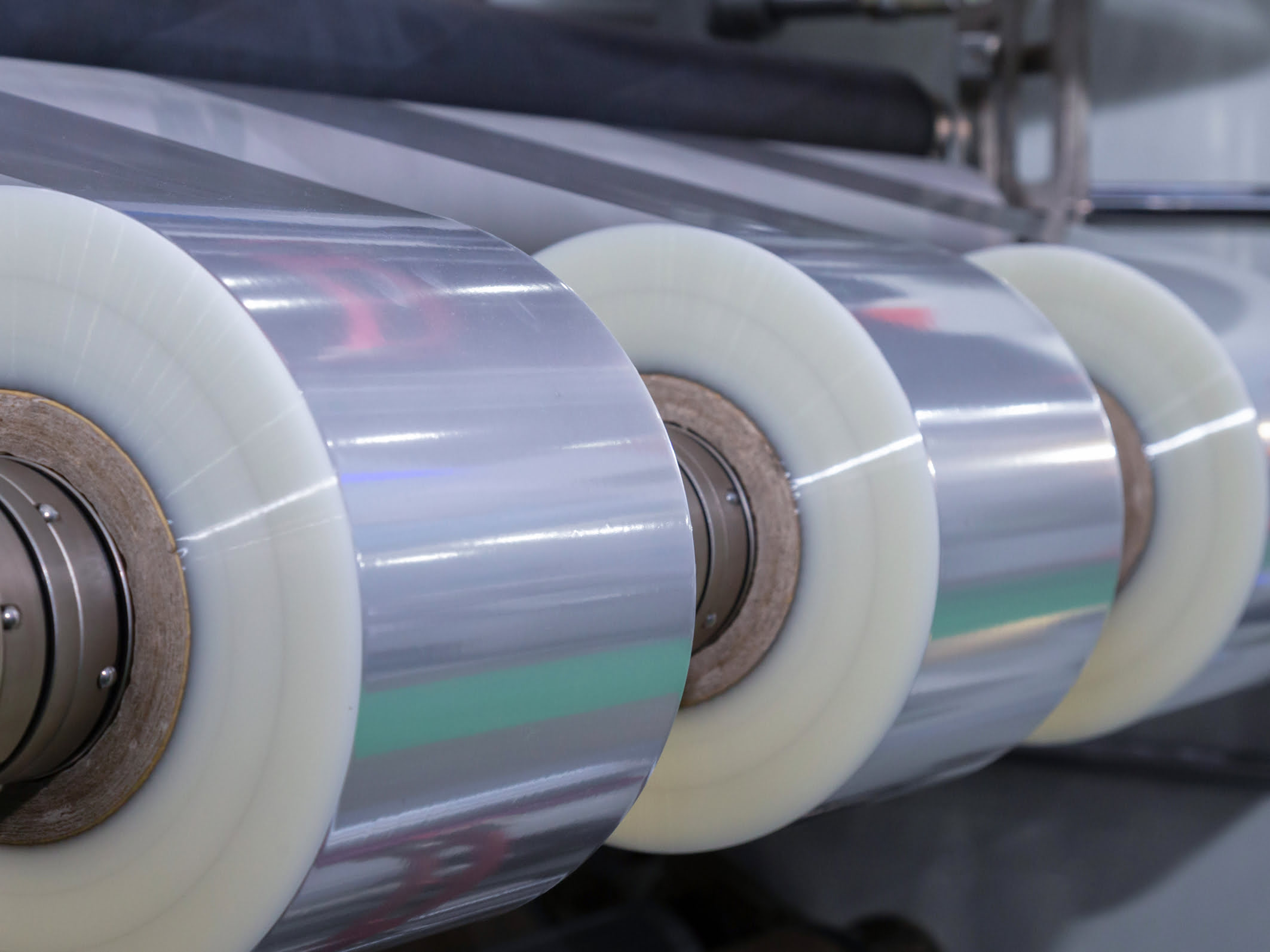

CARDBOARD CORES FOR PLASTIC FILM

cardboard cores

for plastic film

A cardboard tube may appear as a marginal component of industrial production: in reality, its importance makes it closer to a real raw material than a simple packaging component.

For over 40 years Tubitex has been an exceptional partner for the production of tubes, industrial cardboard tubes and cardboard cores for plastic film, capable of satisfying the needs of all kinds of customers.

Our qualified staff and advanced technologies guarantee high and certified standards of excellence in the production of tubes and cardboard cores for packaging and winding of different sizes according to their requirements in terms of company production.

Tubitex is a well-established reality in the paper industry at national and international level specialising in supplying cardboard cores for packaging for high-level industrial productions to graphic, pyrotechnical, paper and other industrial companies.

Cardboard cores for plastic film packaging applications offer exceptional compressive and torsional strength to ensure an adequate response to stress both during and after winding, so that the paperboard substrate holds up well.

We offer cardboard tubes for industrial production that are controlled according to strict criteria during the entire processing cycle thanks to our experienced staff and advanced equipment.

We are involved in the production of cardboard cores for normal, spiralised and rectified films, also customised to help companies achieve standards of excellence in packaging paper production.

Our cardboard tubes are suitable for wrapping various materials such as:

- plastic film

- adhesive tape

- cling film and aluminium foil

- fabric

- paper

- electrical cables

with the possibility of internal and external customisation to suit the industrial production in question.

We also take care of installation processes, solving problems related to product evolutions or new installations.

experience and expertise at your service

Our careful paperboard production for large plants is able to tailor the production of parts to the individual customer’s requirements. Tubitex production of cardboard cores for winding and plastic film includes production in:

Polypropylene

Polyethylene

Packaging in general

PVC

Polyester

Photographic films

Coupled films

Printed films

Films for the food industry

Polythene (including stretch film)

the advantages

The Tubitex cardboard tubes provide customers with constant and long-lasting protection.

Tubitex’s productions of Cardboard cores for plastic film include:

Tubes for the food and fresh food sector

Tubes for plastic film and flexible packaging

Paper mill pipes

Hoses for textile industry

Tubes for containers

Large pipes

ø Inner core | 50 to 120 mm

ø Inner core 50 to 120 mm

Max. core length | up to 3500 mm

Max. core length up to 3500 mm

Max. Thickness | 15mm

Max Thickness 15mm

Max. strength | max 4500 N/100mm

Max. strength 4500 N/100mm

Special customizations

– covers certified for food contact

– adhesive surface, with or without liner, etc.

with Rfid, Green or traditional type, etc.

Special customizations

– cover dyed in the mass according to colour chart

– smooth, embossed, crepe, siliconised surface, etc.

– internal and/or external printing in 1 or more colours (CMYK)

– sealed edge, varnished, etc.

rectified surface (see product family)

Tubitex manufactures cardboard cores to meet any size requirement that can be customised on request. The advantages of cardboard cores for plastic film produced by Tubitex include: